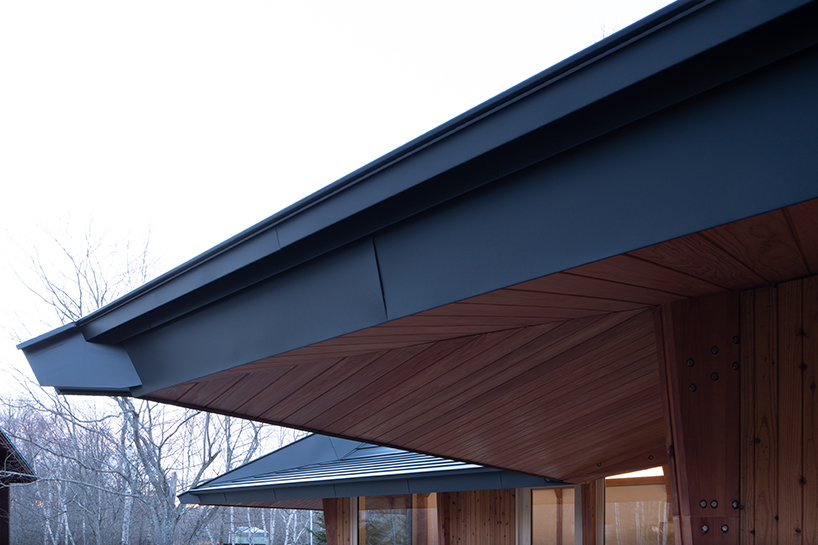

compared to conventional Japanese timber construction, the house’s walls are much thicker for better thermal performance

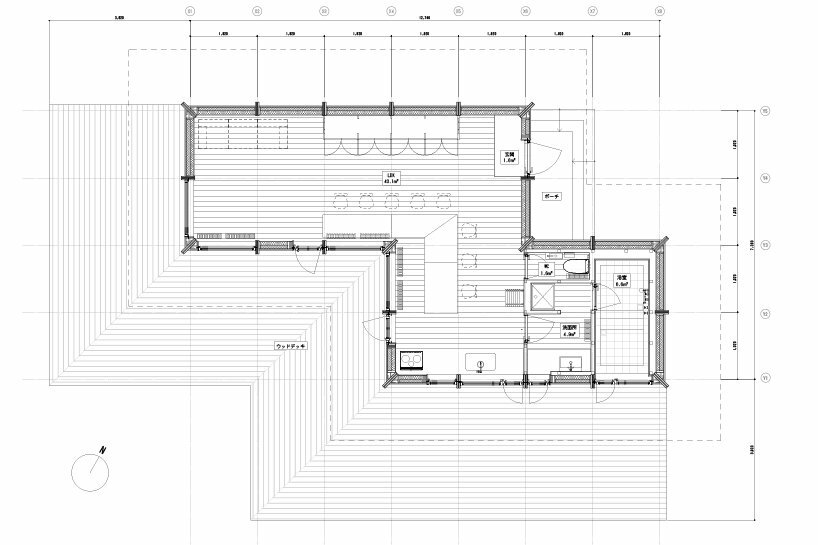

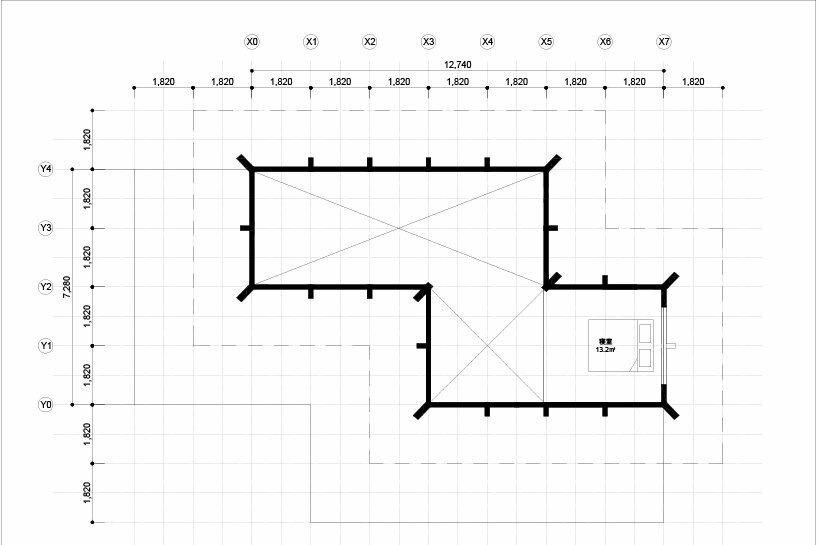

NESTING 0001 elevation

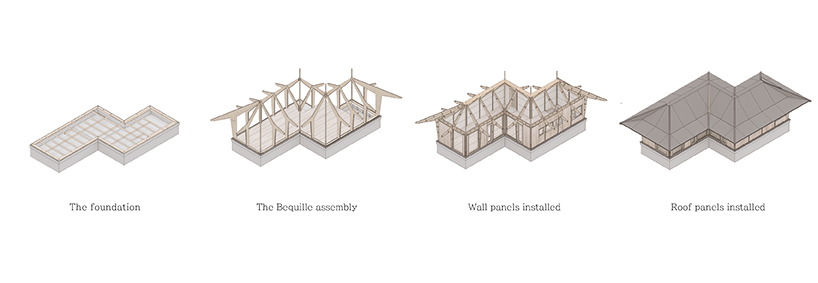

based on this first prototype house, NESTING will provide a real time estimate to a given design

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening now! stepping into the world of manufacturing company .mdd, operating internationally and producing over one million m² of office furnishings per year.

PRODUCT LIBRARY

casa sabater has been designed by fran silvestre arquitectos to descend gradually down a grassy hillside in alicante, spain.

architect jan tyrpekl builds this zen house with a compact timber structure elevated among the trees on stilts.

unlike typical mobile houses, NOT A HOTEL ANYWHERE has its programs scattered across the trailers for a more enriching experience.

connections: +110

nestled on the outer crescent of palm jumeirah island, arada's luxurious development hosts 53 residences, including two presidential suites.